fleet scooter

Background

A purpose-built electric scooter for shared fleet use. Designed for safety, robustness, cost and serviceability, this scooter launched in 2019 and tackled major industry issues surrounding user safety and profitability using existing consumer-grade vehicles.

contributions

Vandalism-proof 6061-T6 chassis weldment

IP67-rated motor controller assembly

Mechanical vehicle architecture and removable battery feature integration

Injection molded covers and elastomer deck mat

Integration and management of various COTS/MOTS parts

Top-level assembly and BOM management

DFM and quality liaising with suppliers, including site visits and FAI

Pilot fleet root cause analysis and remediation

quick facts

Lifecycle Phases: Concept Development & Architecture, Detailed Design, Validation, NPI/Tooling, Production Support

Production Quantity: 50k units +

Development Time: 9 months

Range: 60 mi

Top Speed: 20 mph (limited)

System Ingress Rating: IP67

Onboard Connectivity: GPS, Bluetooth, Wifi

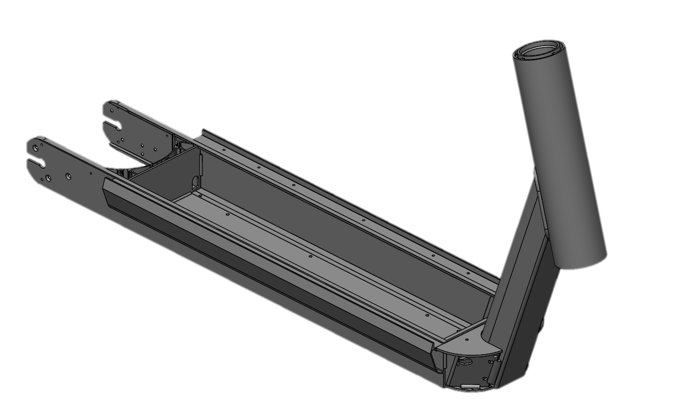

chassis weldment

objective

Design a scooter chassis using existing bicycle-industry manufacturing methods which can withstand harsh abuse associated with shared usage, such as jumping off of, or riding down stairsets.

result

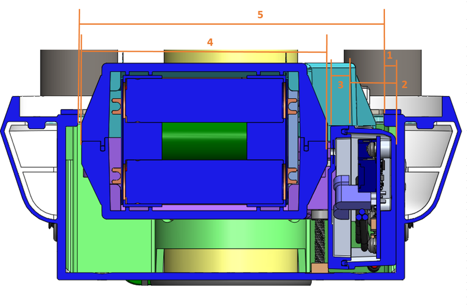

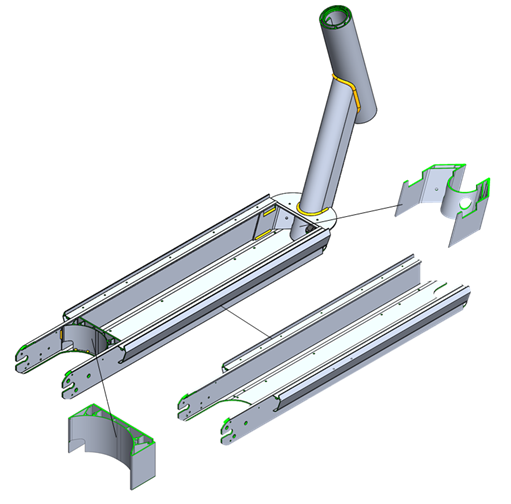

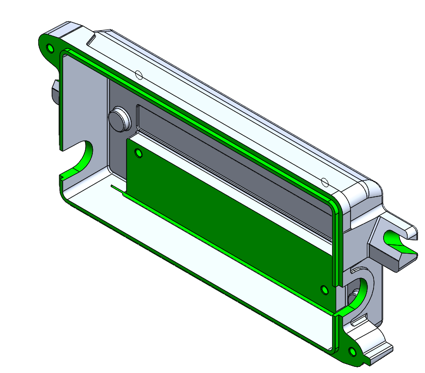

objective

Tolerance stackup of battery and motor controller inside chassis to ensure installation and serviceability

A weldment comprised of 6 custom extrusions, made from 6061 Aluminum was selected for its cost effectiveness and commonality in high-volume bicycle manufacturing . The extruded subcomponents are postmachined, robotically welded, then heat treated to achieve a uniform T6 temper before powdercoating and adding cosmetic finishes. A reinforcement collar added to the neck joint with nearly twice the weld length of other designs prevents failures at this critical joint.

This resulted in a strong, light chassis design that addressed fleet operators’ needs for serviceability and cost-effectiveness, and experienced no major field failures, maximizing user safety. Contemporaneous fleet scooters lasted an average of 3 weeks before decommissioning or disposal, whereas this design was in service for months to years in many cases.

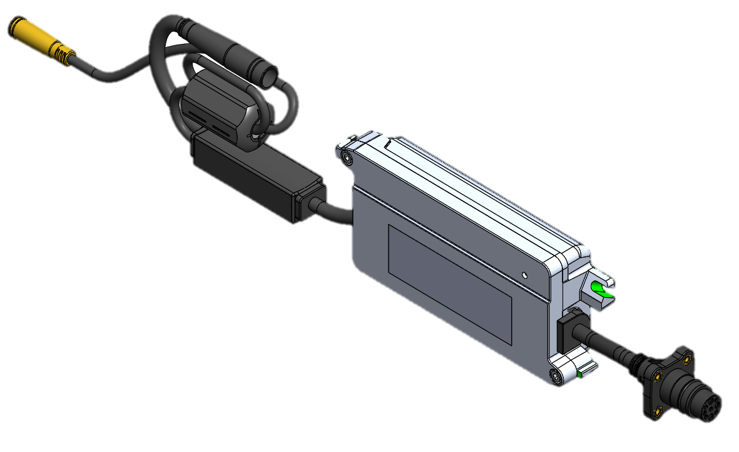

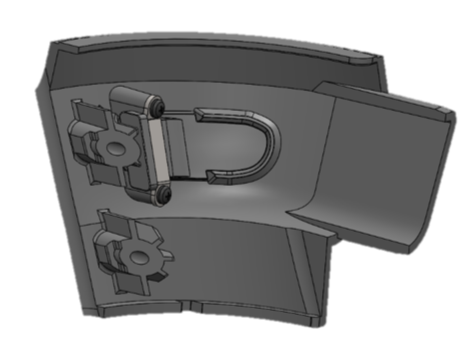

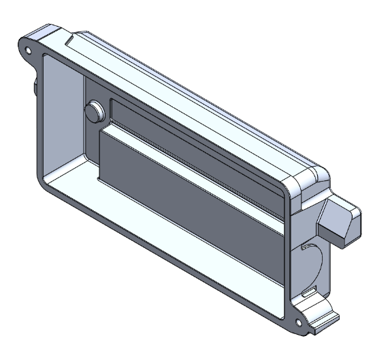

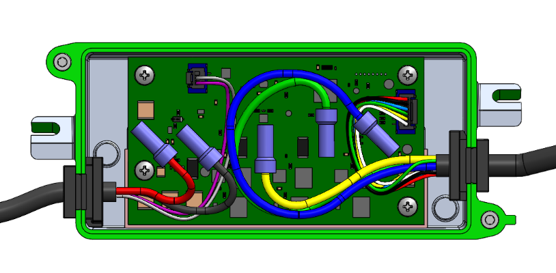

motor controller assembly

Design an environmentally sealed housing for a PCB, with cable exits, thermal transfer paths, and can be replaced as a subassembly.

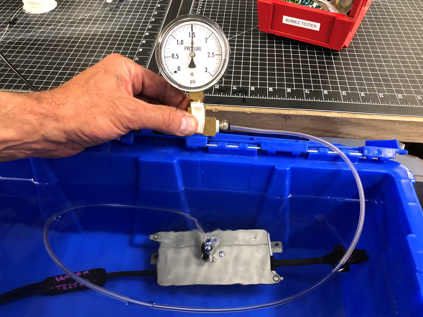

The assembly was submersion tested and met IP67 ingress ratings. The connectorized assembly is easily serviced with the chassis deck removed, and the metal housing provides adequate thermal tdissipation for sustained high-current throughput in the PCB.

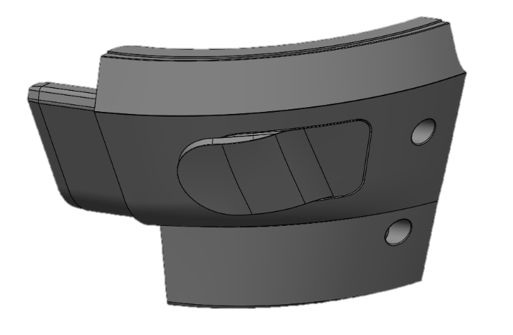

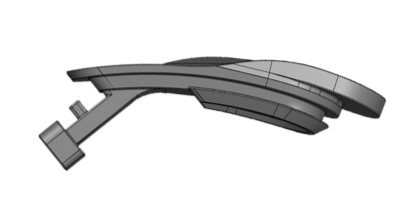

deck trim & chargeport door

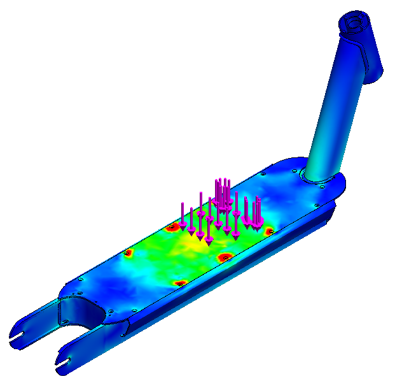

Consumer-grade chassis failure common in early fleet scooters, yield shown in red

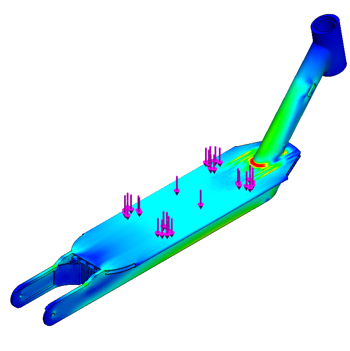

Validated chassis with margin at neck joint

(local concentrations around fasteners do not contribute to failure)

Chassis weldment showing several subcomponents

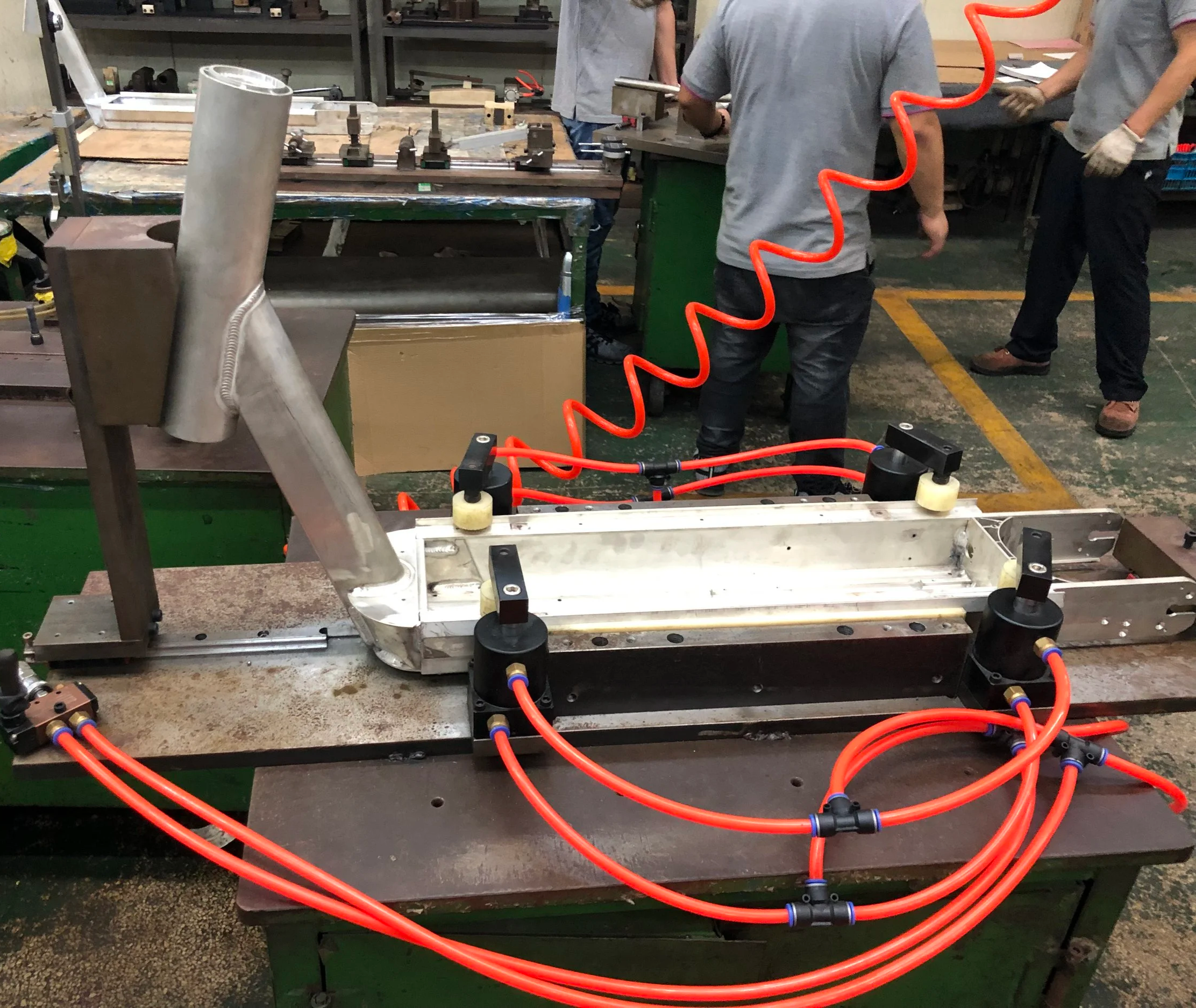

Robotic welding fixture on manufacturing line

method

Working with an Electrical counterpart, a form factor and PCB footprint was established that would fit inside the chassis and could house all the components needed to transmit around 500W of power between the battery and motor

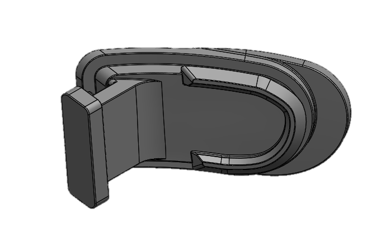

A two-piece semi-solid (SSM) casting of A380 Aluminum constitutes the base and lid of the housing. Custom cables with overmolded seals route power and signal in and out of the box, and a gap pad transmits excess heat from the PCB to the housing, and ultimately to the chassis.

A seal gland designed for RTV sealant or a silicone gasket makes the assembly watertight. The inclusion of a Gore breather vent in the lid allows pressure to equalize in the assembly as temperatures vary.

Overmold bond testing

Positive pressure testing for leak paths

Complex curvature designed for simple two-piece molding resulting in inexpensive, easily replaceable polypropylene parts

Early tooled part fit check

Net Cast Housing Base

method

Using a combination of hand calculations, a data acquisition system with strain gauges, and FEA, a simulation was built to represent the extreme loads on the chassis neck joint.

Competitive analysis was conducted on an existing fleet scooter which exhibited failures at this joint, compromising user safety. The simulation accurately reproduced the field failures, and was used as a tool to compare conceptual designs.

Conceptual chassis designs were then generated and iteratively optimized for weight until the simulation showed adequate margin to failure. All welds were modeled with contact sets to accurately simulate load paths between components.

As subsystems which were housed inside the chassis like the battery and motor controller co-evolved, constant cross-functional communication and fit checking took place to ensure compatibility. Features for internal cable routing, component mounting, and tool access were integrated to maximize serviceability and robustness.

Silicone rubber chargeport door with living hinge and integrated retention features

Chargeport door abuse testing

Cables and connectors modeled in place to ensure proper lengths and bend radii

result

Finished housings with static seal

Postmachined Surfaces