hybrid electric drivetrains

contributions

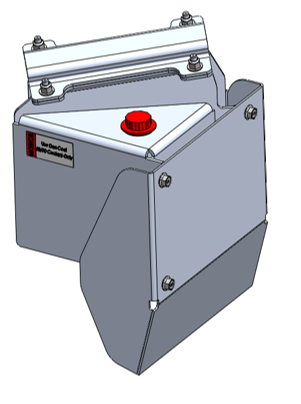

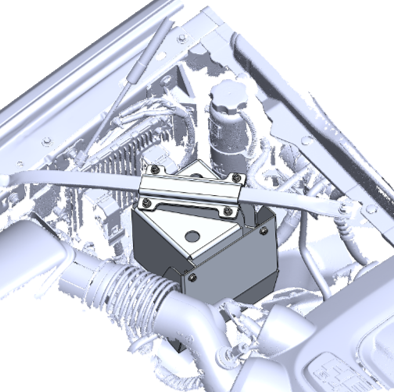

Responsible for design and overall mechanical development of Ram and Ford F-550 integration kits, from feasibility studies to production release

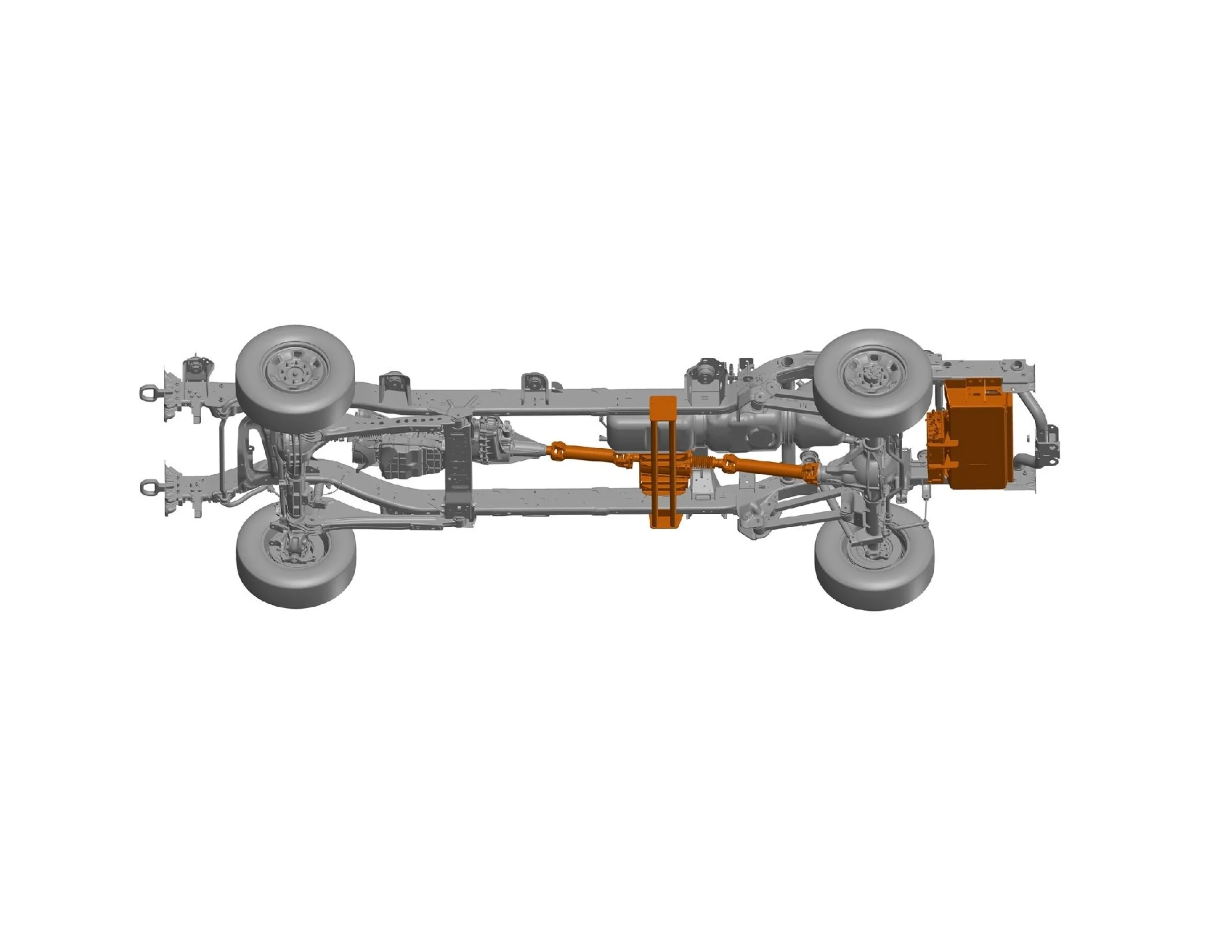

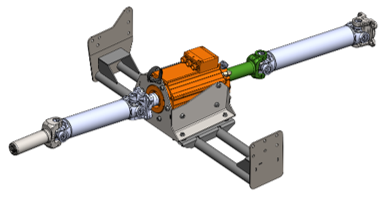

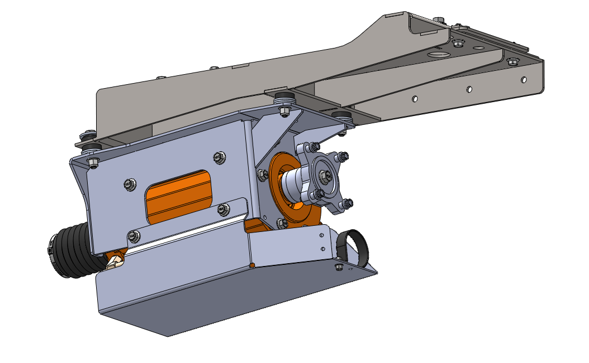

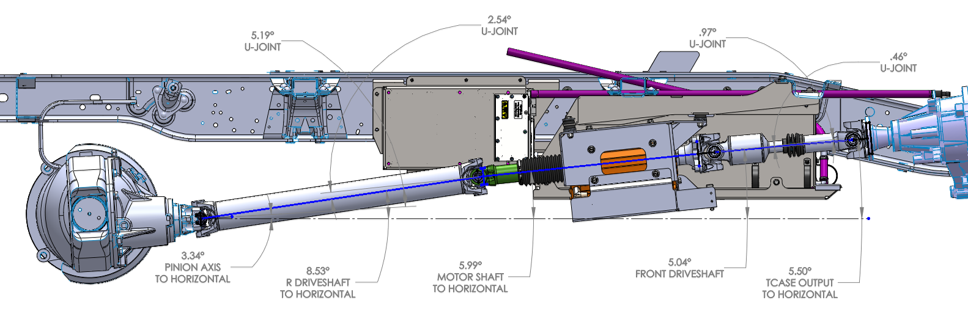

Integrated battery packs, inverters, electric motors, telematics and control units, custom driveshafts, and custom bracketry associated with these subsystems to form a complete system

Designed custom components using a combination of OEM CAD models, 3D scanned data, and physical templates

Constructed and managed configurable system assembly models for each product, including multiple wheelbases and drivetrains

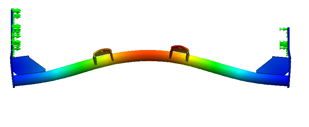

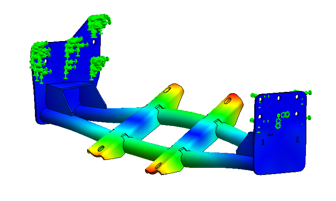

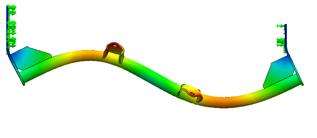

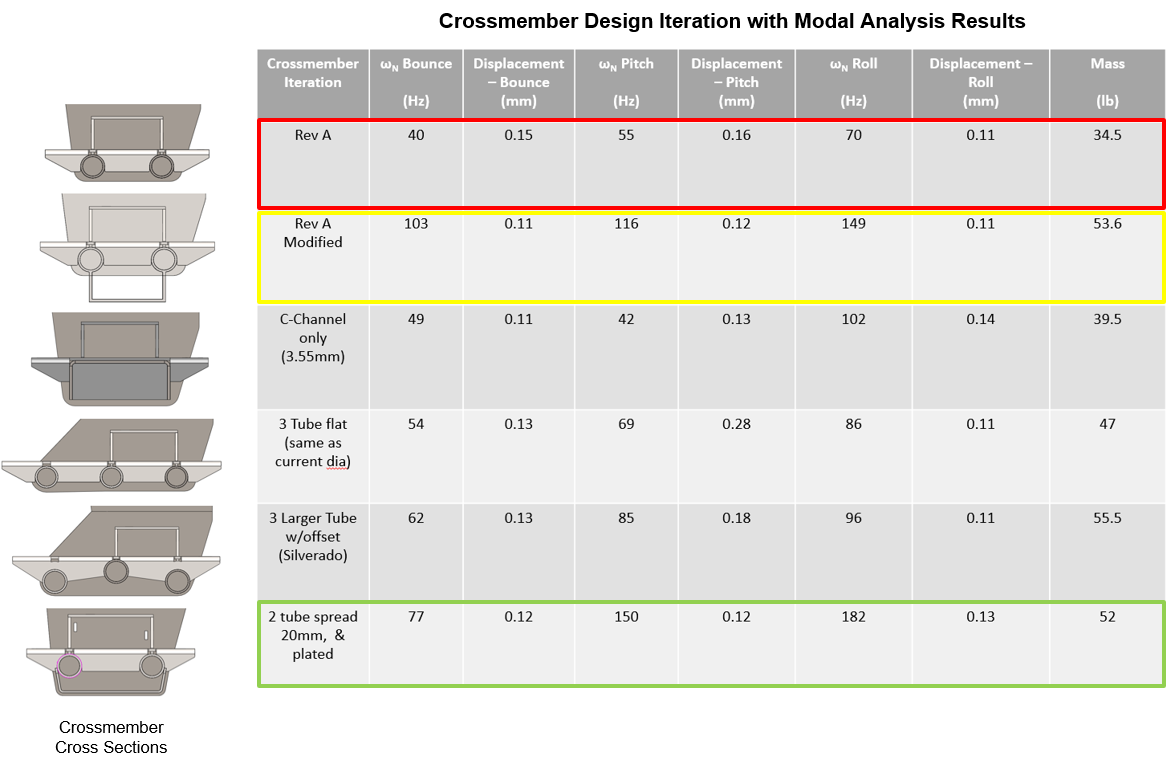

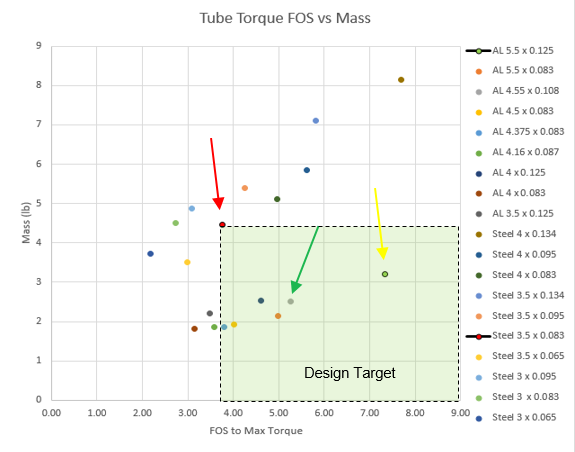

Mitigated drivetrain NVH and drivability issues in more complex refinement by conducting modal analyses and iteratively refining subassembly designs

more information coming soon!

background

These hybrid-electric retrofit kits addressed a need for fuel economy improvement in large, fleet-owned vehicles, and converted factory ICE vehicles to HEV or PHEV as part of the upfit process (bodies, liveries, etc) before fleet deployment

Common vehicles included heavy-duty pickups, shuttle buses, and cargo trucks

Fuel economy was improved by up to 25% using these kits

Systems warrantied for up to 3 years or 75,000 miles